Overview

IS 1161:2014 covers steel tubes and hollow sections intended for structural use. BIS (ISI) Certification confirms compliance on material chemistry, mechanical performance, dimensional tolerances, weld integrity, marking and traceability—enabling lawful sale in India and acceptance in government and infrastructure projects.

A BIS license permits use of the ISI mark with CM/L number, assures buyers of consistent quality, and reduces risk of failures in load-bearing applications.

- Material & Grades – Chemistry limits (C, Mn, S, P) aligned to IS 1161; suitable for welding and forming.

- Mechanical Properties – Tensile/yield strength and elongation per grade; bend/flattening where applicable.

- Dimensions & Tolerances – OD/width, thickness, ovality, length, straightness, and squareness controls.

- Weld Quality – Sound seam for ERW/HFIW; NDT/visual checks and macro as specified.

- Marking & Traceability – ISI mark with CM/L, grade, size, heat/lot/batch identification.

- Factory Production Control – In-process checks, test plans, calibration, and documented release criteria.

- Packing & Handling – Damage prevention, corrosion protection, and bundle identification.

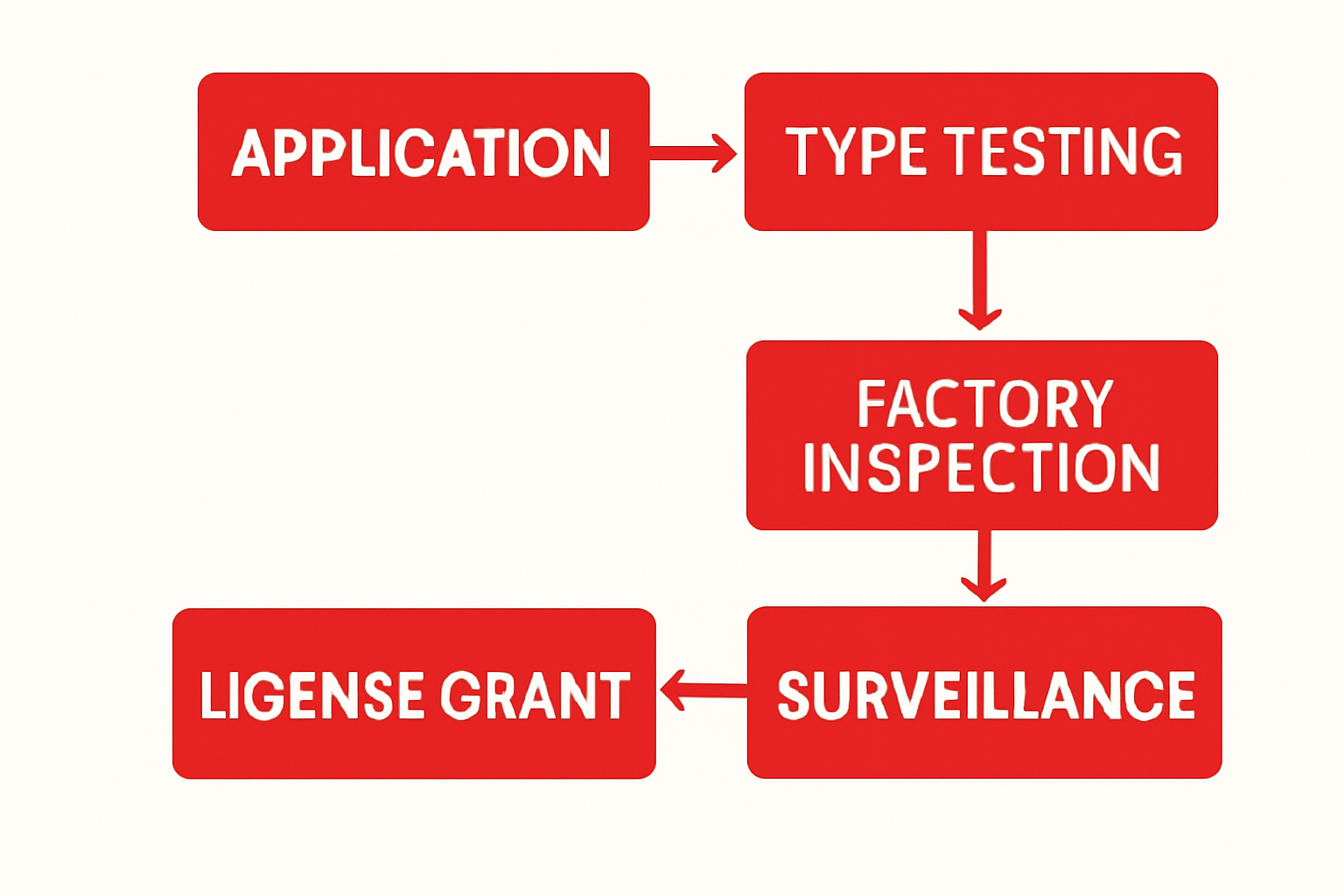

Certification Process

- Application – Grades, shapes/sizes, process, heat treatment.

- Type testing – Chemistry, tensile, bend/flattening, NDT, dimensions.

- Factory inspection – Coil QC, weld/HT records, gauges/NDT, traceability.

- License grant – CM/L; tube marking finalized.

- Surveillance – Lot checks and periodic audits.

Why Choose Us?

- Steel sector specialists with ex-BIS auditors

- End-to-end ISI documentation & liaison

- Template packs for FPC, test records, and traceability

- Fast-track readiness with mock inspections

- Single window for BIS, ISO, CE, and more

Our Services

- BIS Certification (ISI Mark)

- ISO Certification (9001, 14001, 45001, 22000)

- CE Certification

- RoHS Registration

- Business Certificates & Documentation