Overview

GMP (Good Manufacturing Practice) sets the baseline requirements for facilities, equipment, processes, and people to consistently produce safe, high-quality products. It’s widely applied to pharmaceuticals, medical devices, nutraceuticals, foods, and cosmetics.

GMP Certification demonstrates robust process controls, traceability, and compliance with regulatory expectations—boosting market access, partner confidence, and brand credibility.

- Facility & Layout – Hygienic design, zoning, utilities, pest control.

- Equipment – Qualification, calibration, maintenance, and cleaning.

- Materials – Vendor qualification, receipt, storage, FEFO/FIFO, status labeling.

- People – Training, gowning/PPE, health & hygiene, role clarity.

- SOPs – Controlled procedures for production, QC, sanitation, deviations.

- Change & Risk – Change control, CAPA, risk-based decision making.

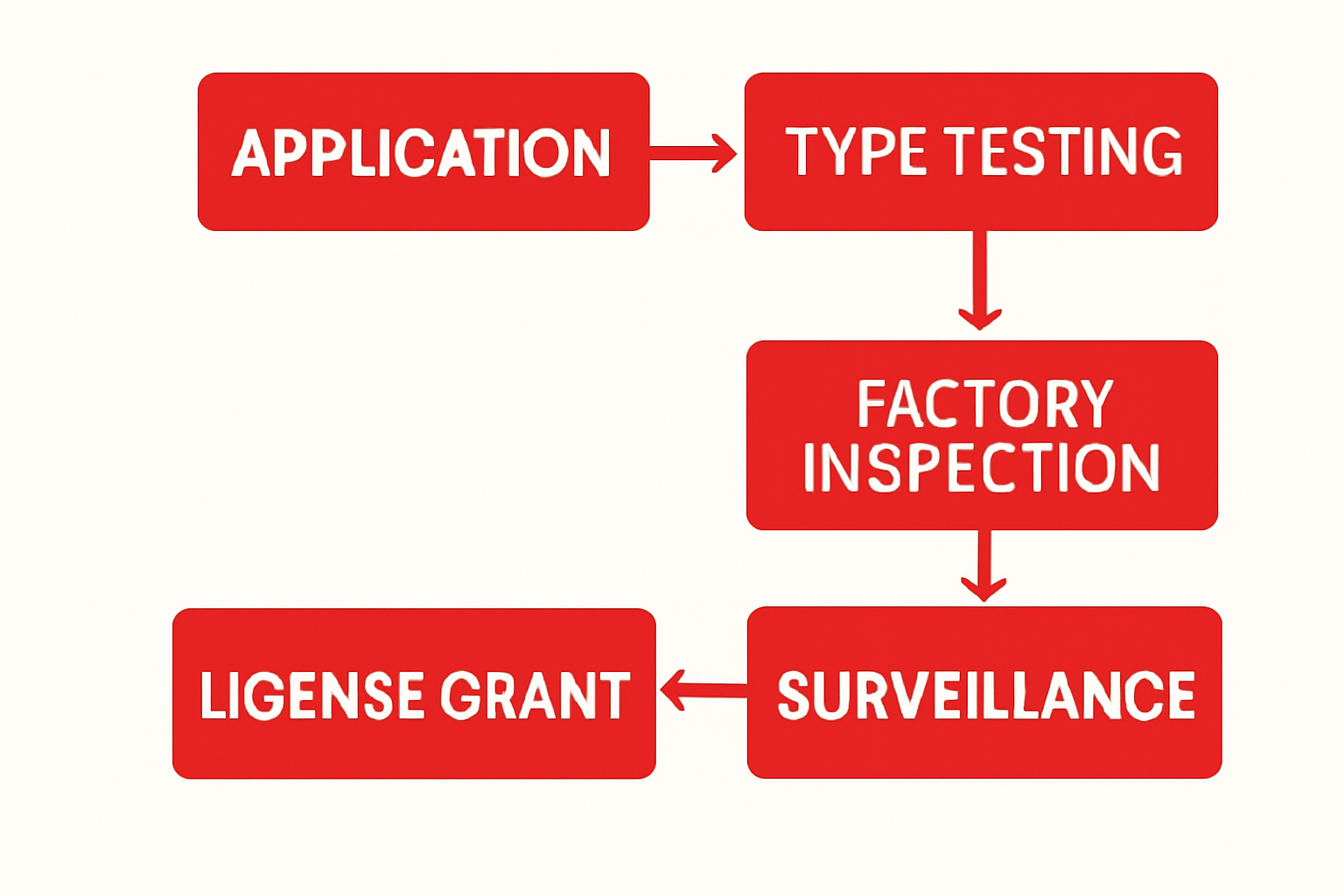

Certification Process

- Application – Scope, product categories, sites, and current controls.

- Gap Assessment – Audit vs GMP code; corrective action plan.

- Implementation – SOPs, training, qualifications, validations, CAPA.

- Stage Audit – Documentation review + on-site verification.

- Certification – Issue certificate; define surveillance frequency.

- Surveillance – Periodic audits & continuous improvement.

Why Choose Us?

- Ex-regulatory & industry GMP experts

- Ready-to-use SOP packs & validation templates

- Mock audits and rapid NC/CAPA closure

- Single-window for GMP + ISO (9001/13485/22000)

- End-to-end project management with clear timelines

Our Services

- GMP Gap Assessment & Roadmap

- SOPs, Training & Documentation

- Equipment/Process/Cleaning Validation

- Internal Audits & Supplier Qualification

- Certification & Surveillance Support